How Multi-Material Printing Transforms Low-Cost Silicone Prototyping

Why Multi-Material Printing is the Future of Silicone Prototyping

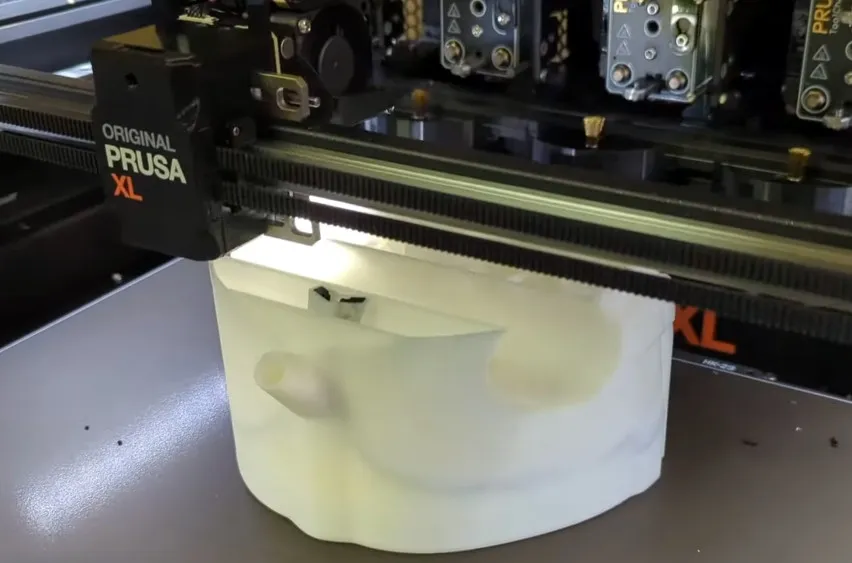

In today's fast-paced tech environment, Multi-Material Printing stands out as a game-changer for low-cost silicone prototypes. Traditional injection molding methods, while excellent for mass production, pose challenges in prototyping due to their high costs and long lead times. Multi-Material Printing allows for rapid prototyping, facilitating quick iterations and cheaper production without sacrificing quality.

Benefits of Multi-Material Printing

- Cost-effective solutions for early-stage product development

- Speed advantages, enabling quick adjustments to designs

- Increased design freedom with varied material use

Conclusion: The Shift Towards Innovative Prototyping

As technology advances, the importance of Multi-Material Printing in producing affordable silicone prototypes becomes increasingly clear. The tech industry stands to benefit significantly from these innovative methods, leading to a faster development cycle and reduced financial overheads.

This article was prepared using information from open sources in accordance with the principles of Ethical Policy. The editorial team is not responsible for absolute accuracy, as it relies on data from the sources referenced.