3D Printing News: Knust-Godwin Partners with Continuum Powders for Oil and Gas Project

Knust-Godwin and Continuum Powders Partnership

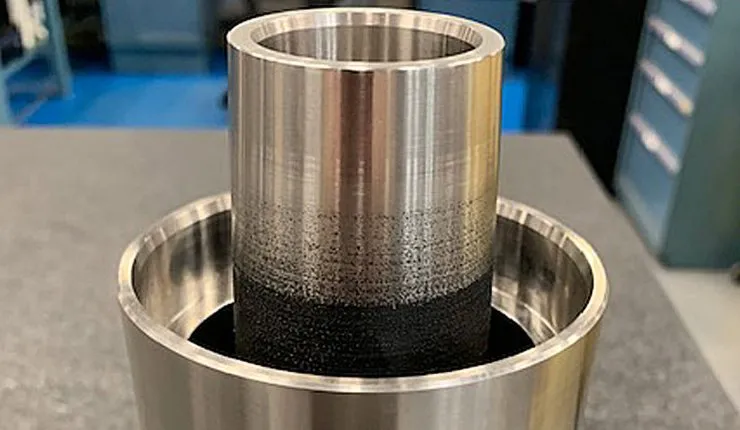

In a significant move for 3D printing in the oil and gas sector, Knust-Godwin has announced that it will work exclusively with Continuum Powders to supply metal powders for its upcoming projects. The focus of this partnership is to leverage metal additive manufacturing to meet the needs of large-scale industry customers.

Benefits of Metal Additive Manufacturing

- Increased Efficiency: Streamlined production with reduced waste.

- Enhanced Sustainability: Recyclable materials contribute to eco-friendly practices.

- High Precision: Ability to create complex geometries and customized parts.

About the Project

The partnership will primarily focus on a substantial project for a major oil and gas client, which aims to recycle nickel alloy parts efficiently. This venture highlights the growing importance of additive manufacturing technologies in heavy industry.

This article was prepared using information from open sources in accordance with the principles of Ethical Policy. The editorial team is not responsible for absolute accuracy, as it relies on data from the sources referenced.