3D Printing News: High-Pressure Techniques Revolutionize Additive Manufacturing

3D Printing News: Understanding High-Pressure Techniques

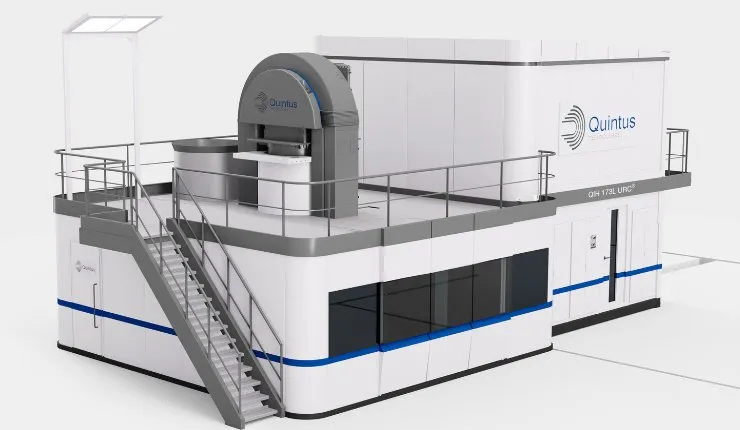

3D printing is undergoing a remarkable transformation, especially with the integration of high-pressure technologies. Hiperbaric and Quintus Technologies are pioneering the use of hot isostatic pressing (HIP) in 3D printing. This innovative approach solidifies the manufacturing process by applying intense pressure to metals, allowing for improved post-processing of printed parts.

Significance of High-Pressure Processing

- Accelerates Production: High-pressure processing shortens the time required to produce high-quality components.

- Enhances Material Properties: The applied pressure increases the density and strength of the printed materials.

- Facilitates the use of diverse metal types, expanding the applications of additive manufacturing.

Industry Impact and Future Prospects

The innovations introduced by Hiperbaric and Quintus are setting new standards in 3D printing. As highlighted by Laura Griffiths, these advancements not only promote efficiency but also promise to significantly alter how parts are fabricated in various industries. For anyone interested in the evolving landscape of 3D printing news, staying updated on these technological leaps is essential. For further information, it's suggested to visit the source.

This article was prepared using information from open sources in accordance with the principles of Ethical Policy. The editorial team is not responsible for absolute accuracy, as it relies on data from the sources referenced.