3D Printing News: Velo3D Reduces Workforce to Streamline Metal Additive Manufacturing Costs

Velo3D's Cost-Cutting Strategy in 3D Printing

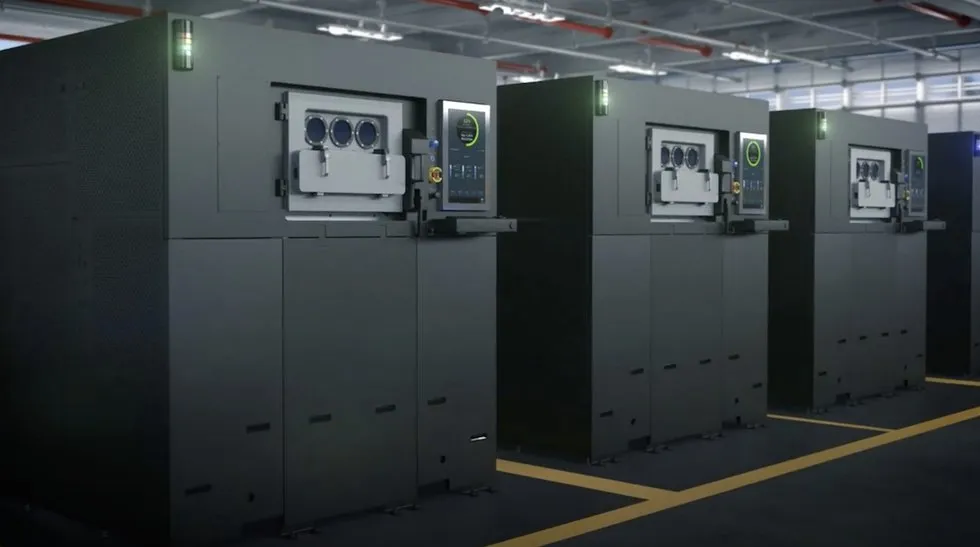

In a significant move within the 3D printing sector, Velo3D has announced its decision to reduce its workforce by 30%, affecting around 63 employees. This decision comes in the wake of challenges faced from project delays in government-funded initiatives, prompting a reevaluation of their Metal Additive Manufacturing direction.

The Impact of Decision on Metal Additive Manufacturing

As the landscape evolves, Velo3D's strategic choices highlight the realities confronting startups in the additive manufacturing domain. The reduction in workforce aims to adjust to the primary objective of controlling escalating costs while continuing to innovate and lead within the 3D printing industry.

- Project Delays

- Workforce Reduction

- Financial Pressure

- Innovation Strategy

This article was prepared using information from open sources in accordance with the principles of Ethical Policy. The editorial team is not responsible for absolute accuracy, as it relies on data from the sources referenced.